Single Panel

Let’s understand what is termed as a single panel wall:

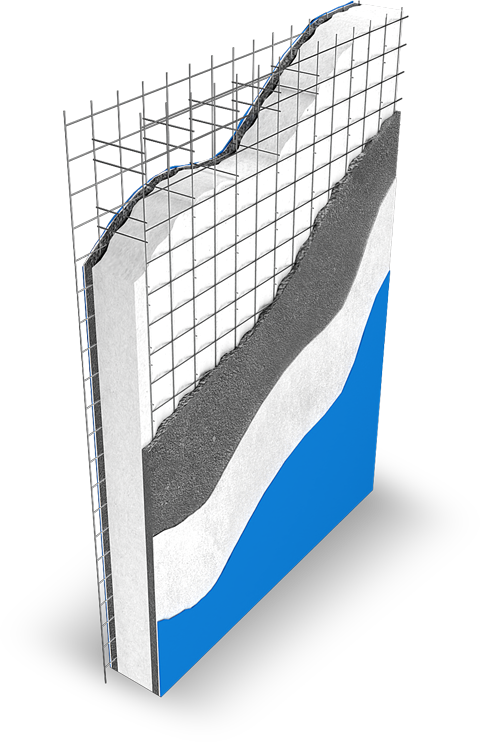

The key components of a reinforced concrete

sandwich panel are as follows:

These are the two layers of concrete that form the exterior surfaces of the panel. They provide protection from the elements, contribute to the structural integrity of the panel, and can be designed with various architectural finishes and textures. Concrete is a strong and durable building material known for its compressive strength. In the case of Sandwich Panels, it is often used in a precast form to ensure quality and consistency.

The insulation material is placed between the two concrete wythes. It serves as a thermal barrier, helping to regulate the temperature inside the building. We use expanded polystyrene (EPS) in these panels.

To enhance the structural strength of the panel, steel reinforcement, such as rebar, is incorporated within the concrete layers. This reinforcement helps the panel withstand loads and stresses, such as wind and seismic forces. The reinforcement in wythes is provided in the form of welded TMT- bars in longitudinal and transverse directions. The outer layers (wythes) are inter-connected either by shear connectors (orthogonal or inclined wires. The function of shear connectors is to hold the wythes and core in place, as well as to transfer the longitudinal shear between the wythes.

Insulated single panel walls are commonly used in the construction industry to create exterior walls and facades in both residential and commercial buildings. They offer a versatile solution for achieving structural integrity, energy efficiency, and design flexibility in construction projects. It is used as a supporting structure, for buildings up to four floors. It is perfect for partitions and claddings; as claddings and partitions wall in large-sized industrial and commercial buildings; as an insulating framework for roofing and moderate floors. These waterproof single panels are approved as a load bearing wall by numerous certifications worldwide viz. the ETA certification in Europe, the ESR evaluation report from International Code Council (ICC) and the Technical Evaluation Report (TER) from Disaster Recovery Journal (DRJ) in the US.