Decoding the complex vocabulary

of construction industry

In a world where construction technology and terminology can seem daunting, this article aims to simplify and clarify the key concepts that are reshaping the construction industry. Aimed at understanding the terminology and innovations that shape the industry, this article serves as a guide unravelling the complex vocabulary and concepts in construction, making it comprehensible for all. We will explore the key terms and technologies that are transforming the construction landscape, from sandwich panels and prefabricated buildings to expanded polystyrene insulation boards (EPS wall panels) and green construction technology, all within the context of sustainable construction practices.

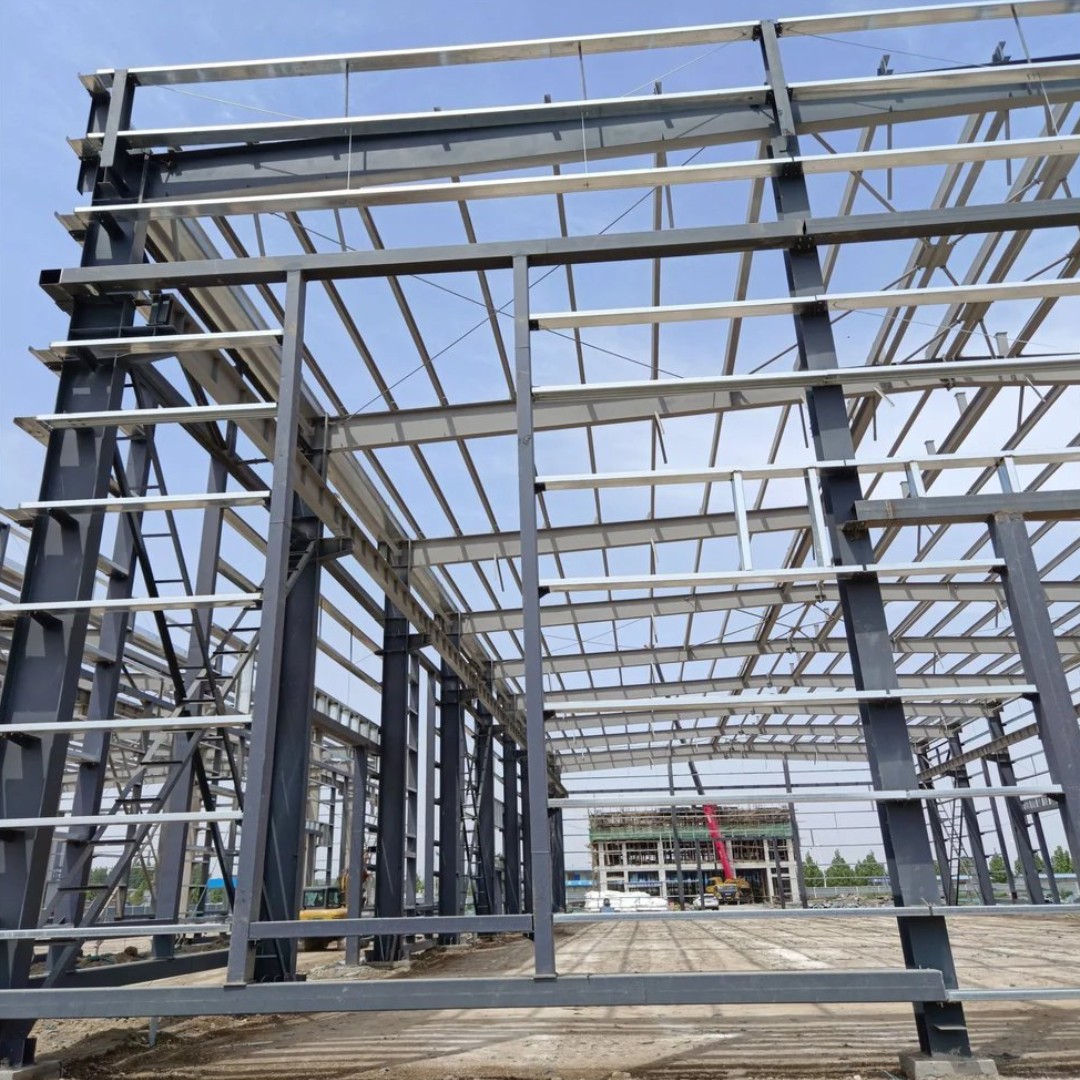

Pre-fabricated building

A pre-fabricated building is a structure made by assembling components pre-fabricated in a factory and then transporting them to the construction site for a quick assembly. These buildings are known for their efficiency, reduced waste, and flexibility in design. They are used for various purposes and are often energy-efficient and cost-effective.

One of the key advantages of pre-fabricated buildings is the efficiency they offer. Since much of the construction work occurs in the factory, where environmental conditions are controlled, there is a higher level of precision and quality control. This results in reduced construction time and less material waste as compared to the traditional on-site construction methods.

Pre-fabricated buildings can be customised to meet specific design and functional requirements. They are available in a variety of architectural styles and can be used for a wide range of purposes, from single-family homes to multi-story office buildings and healthcare facilities.

Transportability is another notable feature of prefab construction. Once the components are manufactured, they can be easily transported to the construction site, even in remote or challenging locations. This makes prefab construction an attractive option for projects with logistical complexities.

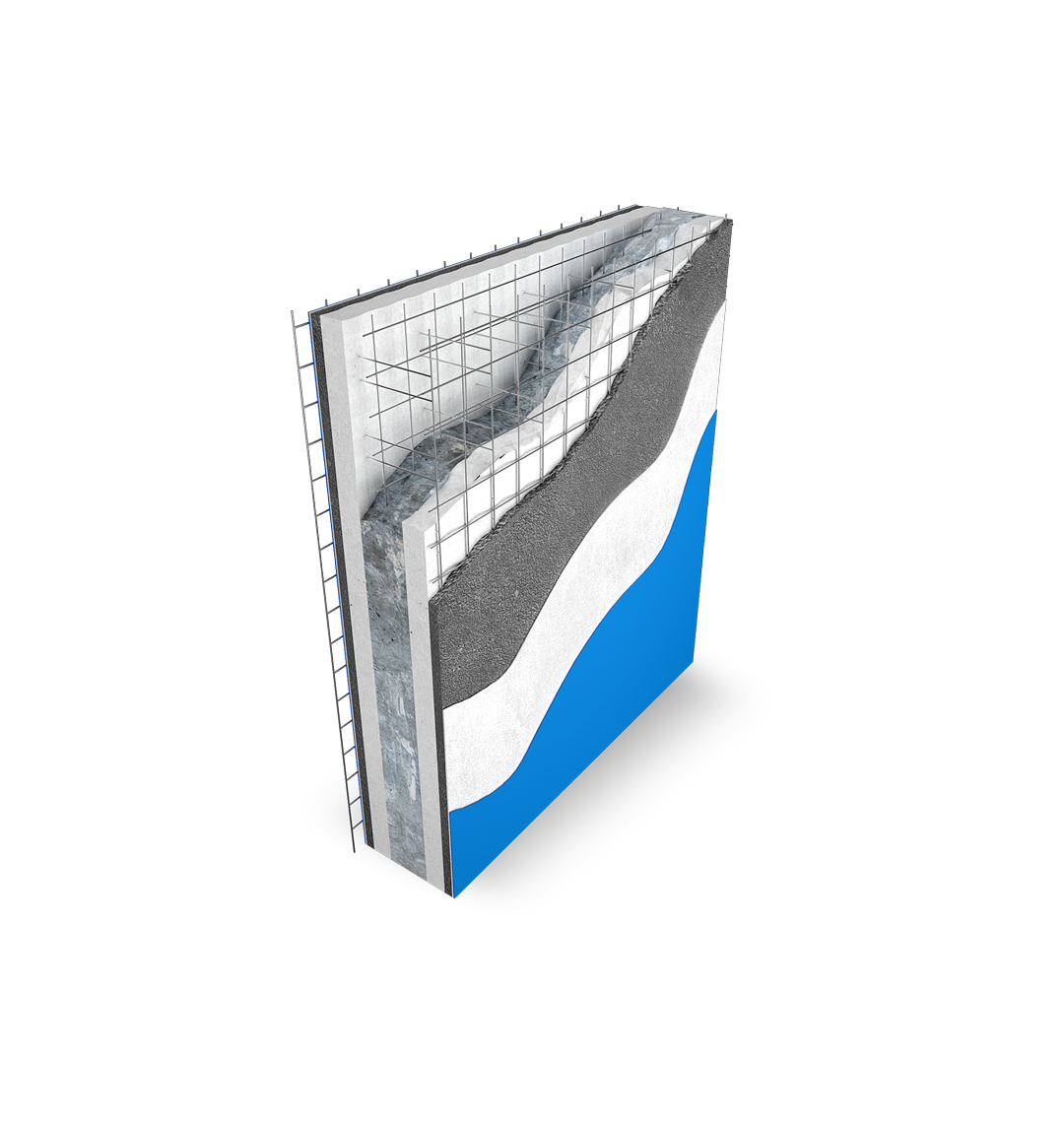

Sandwich panels

Sandwich panels are a type of construction material used in building walls, roofs, and floors. They are called ‘sandwich panels’ because they are made up of three layers, just like a sandwich:

Inner Core: The inner core is the central layer of the sandwich panel. It is typically made of insulating materials like expanded polystyrene (EPS), polyurethane foam (PUF), or mineral wool. This layer provides thermal insulation, helping to regulate indoor temperatures and reduce energy consumption.

Outer Layer: On both sides of the inner core, there are outer layers made of strong and rigid materials such as concrete, steel, aluminum, or other composites. These outer layers give the panel its structural strength and protect the insulation inside.

Inner Layer: In some cases, there may be an additional inner layer on the opposite side of the outer layer. This inner layer can provide further structural support or serve other specific purposes, depending on the panel’s design.

Sandwich panels are known for their excellent thermal insulation properties, making them popular in construction for creating energy-efficient buildings. They are used in various construction applications to enhance a building’s energy efficiency, structural integrity, and overall performance.

Expanded Polystyrene Insulation Boards (EPS insulation boards)

Expanded Polystyrene Insulation Boards (EPS insulation boards) are a versatile and efficient building material primarily used for thermal insulation in construction. These boards are made from expanded polystyrene, a lightweight and rigid plastic foam known for its exceptional insulating properties. EPS insulation boards are designed to reduce heat transfer between the inside and outside of a building, helping maintain consistent indoor temperatures and improve energy efficiency.

Due to their lightweight nature, EPS boards are easy to handle and install, making them a practical choice for construction projects. They are moisture-resistant, cost-effective, and compatible with various construction materials and systems. In addition to their thermal insulation benefits, EPS boards also offer some sound insulation properties, contributing to a quieter indoor environment. Furthermore, they are environmentally friendly, as they can be recycled, and many manufacturers use recycled content in their production, minimizing their environmental impact.

In summary, EPS insulation boards play a crucial role in construction by providing effective thermal insulation, reducing energy consumption, and enhancing overall building comfort. Their versatility, affordability, and environmental benefits make them a popular choice for both residential and commercial building projects.

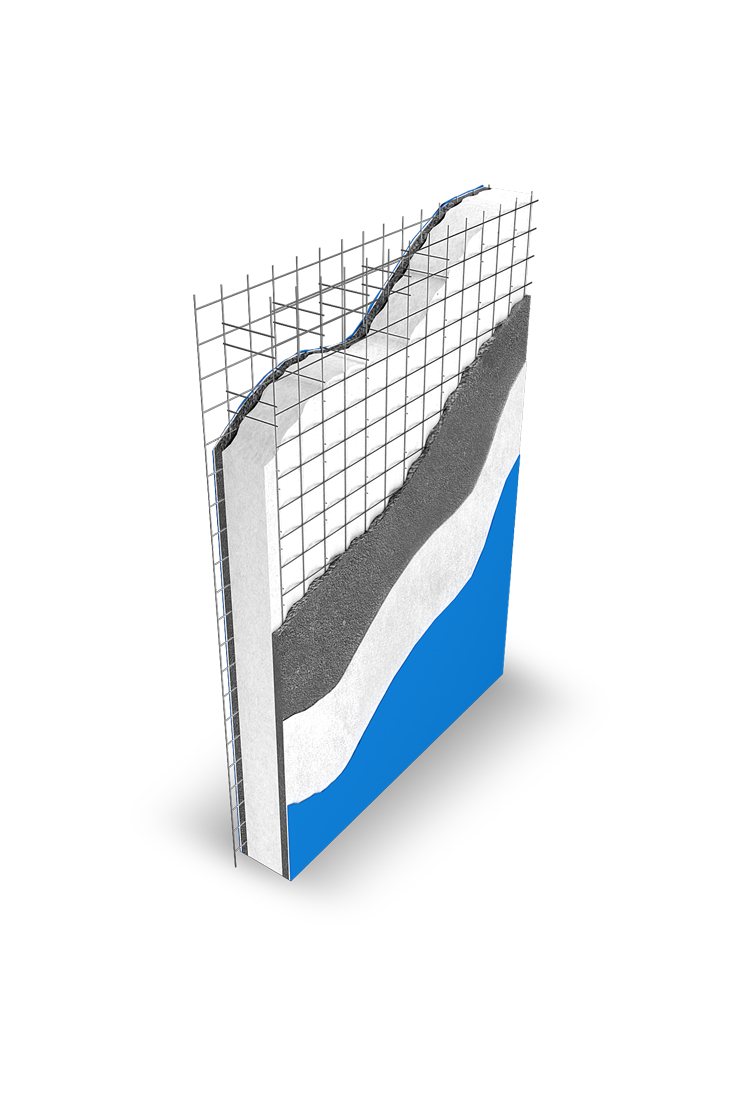

EPS Wall Panels

EPS wall panels, short for Expanded Polystyrene Wall Panels, are a revolutionary construction material designed for building walls in a more efficient and energy-conservative way. These are further classified into different segments, where one is completely factory made, where panels are made of a core of expanded polystyrene foam, known for its exceptional thermal insulation properties, sandwiched between two sturdy sheet boards, typically oriented strand board (OSB) or Gypsum cement-based boards. EPS wall panels provide a unique combination of structural support and superior insulation.

The other being partly factory made and finished at site. These are the ‘Steel Reinforced Concrete EPS Core Panel‘. Here the expanded polystyrene (EPS) panel is encased between two layers of steel reinforced concrete. The EPS panel with the steel reinforcements are factory made and assembled at site, and then covered with shotcrete. This makes the structure monolithic.

The key advantage of EPS panels is their remarkable thermal insulation capability. They significantly reduce heat transfer, helping maintain consistent indoor temperatures and diminishing the need for excessive heating or cooling. This translates to reduced energy consumption, lower utility bills, and enhanced energy efficiency within buildings. Moreover, these panels are lightweight, simplifying installation and saving construction time and labor costs.

EPS wall panels offer structural integrity and can endure various environmental conditions. They can also contribute to sound insulation, creating quieter indoor environments. With their design versatility and sustainability, including the use of recycled materials in production, EPS wall panels are a popular choice for constructing energy-efficient, comfortable, and environmentally responsible buildings in various residential, commercial, and industrial settings.

Green construction technology / Sustainable construction

Green construction technology, often referred to as sustainable construction, is a forward-thinking approach to building design and construction that prioritizes environmental responsibility and resource efficiency. It focuses on creating buildings and infrastructure that have a minimal negative impact on the environment while promoting energy efficiency and occupant well-being.

One of the central aspects of green construction technology is energy efficiency. Green buildings incorporate various design features and technologies to reduce energy consumption, such as improved insulation, energy-efficient lighting and HVAC systems, and renewable energy sources like solar panels. This not only lowers operating costs but also decreases greenhouse gas emissions, contributing to a more sustainable future.

Resource conservation is another key element of green construction. It involves using sustainable materials, reducing waste through recycling and efficient construction practices, and optimizing water usage through features like low-flow plumbing and water recycling systems. Moreover, green construction technology prioritizes indoor air quality by utilizing non-toxic materials and efficient ventilation systems, ensuring that occupants enjoy a healthier and more comfortable living or working environment.

We delved into the world of sandwich panels, highlighting their role in enhancing energy efficiency and structural integrity, pre-fab buildings, known for their efficiency and sustainability, demystified their benefits in reducing waste and construction time. We explored the innovative realm of EPS wall paneling, focusing on their exceptional thermal insulation properties and contribution to energy-efficient construction. Lastly, we introduced the concept of green construction technology, emphasising its role in creating eco-friendly and resource-efficient buildings. This article offers a comprehensive understanding of construction terminology and technologies, particularly in the context of sustainable construction practices.