Readymade Wall Panels : A Comprehensive Guide

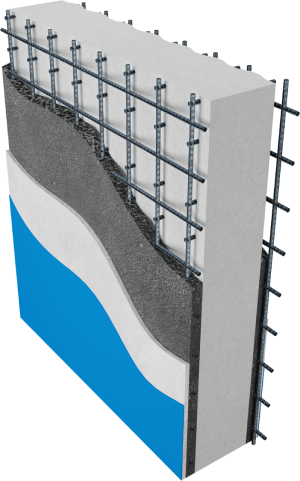

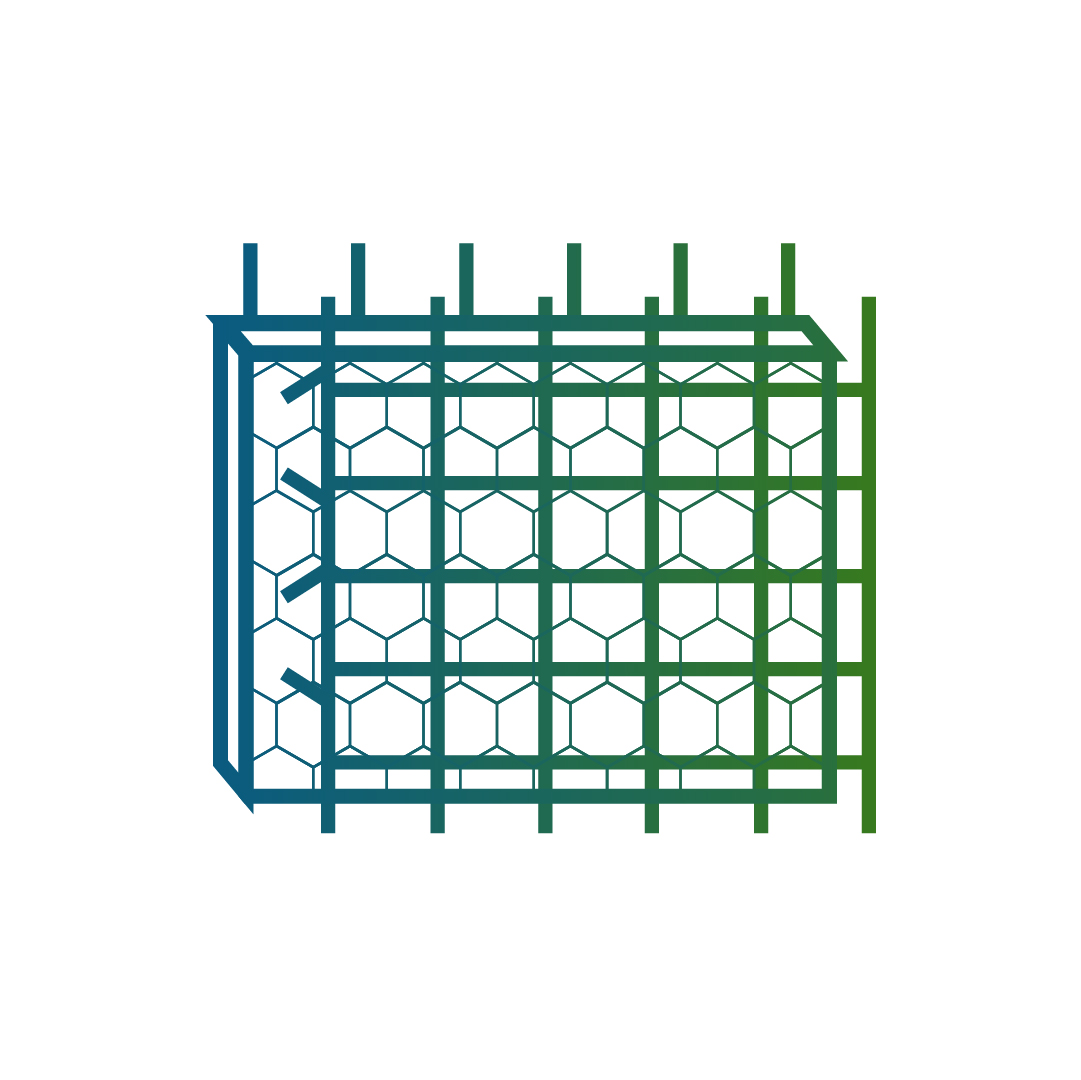

Readymade wall panels, often referred to as sandwich panels for walls or pre-fabricated wall panels, are innovative building components designed to streamline the construction process of any building. These panels consist of multiple layers, typically an insulating core sandwiched between two outer layers known also known as wythes, creating a robust and energy-efficient structure. The materials used in these panels vary, including but not limited to concrete, steel, gypsum boards and insulation materials such as foam or mineral wool.

These panels are precisely manufactured off-site, ensuring superb quality control and precision. The term ‘readymade’ implies that these panels are ready for installation upon delivery to the construction site. This off-site fabrication not only accelerates the construction timeline but also minimizes on-site disruptions and wastage, making Prefabricated buildings an eco-friendly option.

The manufacturing process of readymade wall panels involves several key steps, each contributing towards enhancing the eps panels structural integrity and performance. First and foremost, detailed design and engineering are conducted using advanced software to ensure precise specifications.

Once assembled, the eps panels are subjected to rigorous testing to ensure they meet industry standards and project- specific requirements. The completed readymade wall panels are then transported to the construction site, ready for an efficient installation.

Structural estimations, calculations and allocations

Selecting insulation materials

Manufacturing in different sizes and volumes

Selecting appropriate re-enforcements

Making each unit with insulation material and re-enforcements

The use of advanced sustainable construction technology, including computer-aided design and manufacturing (CAD/CAM), further guarantees the accuracy and reliability of wall blocks. This commitment to precision translates into buildings that not only meet but often exceed structural standards, offering a durable and secure solution for various construction projects.

Passive houses are These wall panels have found extensive use in residential construction, offering homeowners a faster and more efficient building process. These panels are customisable, allowing for diverse architectural designs while maintaining energy efficiency. The speed of construction is particularly advantageous for meeting tight deadlines or accommodating homeowners who seek quicker occupancy.

In the commercial sector, where time is often of the essence, wall blocks shine as a time-efficient and cost- effective solution. From office buildings to retail spaces, the versatility of these panels caters to various design requirements. Their ability to support the installation of utilities, such as electrical wiring and plumbing, further streamlines the construction of commercial structures.

In industrial settings, where durability and functionality are paramount, readymade wall panels offer a robust solution. These panels can withstand heavy loads, extreme temperatures, and harsh industrial environments. The speed of construction is also a significant advantage in industrial projects, minimizing downtime and maximizing operational efficiency.