Double Panel

Let’s understand what is termed as a double panel walls:

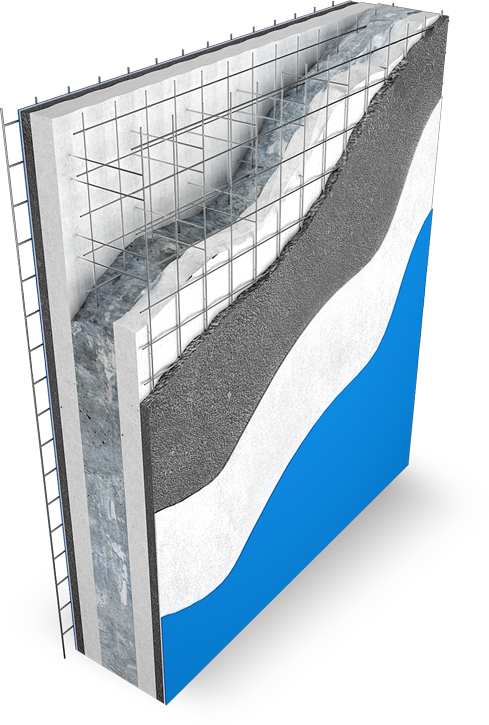

Here the central layer is the thickest layer consisting of high strength, steel reinforced concrete also known as the ‘core’ which is protected on both sides by an insulating material. It serves as a thermal barrier, helping to regulate the temperature inside the building. We use expanded polystyrene (EPS) in these structural insulated double panel wall. The outer layers are again of high strength reinforced concrete often referred as the ‘skin layers’. The wythes or the ‘skin layers’ are usually made of micro-concrete or cement and coarse-sand mortar. In short it is like a club sandwich with three layers of concrete

To enhance the structural strength of the panel, steel reinforcement, such as rebar, is incorporated within the concrete layers. This reinforcement helps the panel withstand loads and stresses, such as wind and seismic forces. The reinforcement in wythes is provided in the form of welded TMT- bars in longitudinal and transverse directions. The outer layers (wythes) are inter-connected either by shear connectors (orthogonal or inclined wires. The function of shear connectors is to hold the wythes and core in place, as well as to transfer the longitudinal shear between the wythes.

The insulated double panel is an ideal option for the reinforced concrete walls such as load- bearing walls and retaining walls. The sound proof double panel is made up of two basic panels, shaped as required, and joined together by double horizontal connectors creating a hollow core between them, to be then filled with concrete of desired strength to meet the project needs. A layer of plaster is then applied to the panel on the outer faces. The double reinforced panel meets building code requirements for reinforced concrete ‘Eurocode 2’ (EC2) and all other building codes recognised across the world.