Curved Panel

Here is an overview of the manufacturing process

for curved reinforced concrete sandwich panels:

The process begins with the design and planning phase, where architects, engineers, and manufacturers collaborate to determine the panel's dimensions, curvature, and other specific requirements.

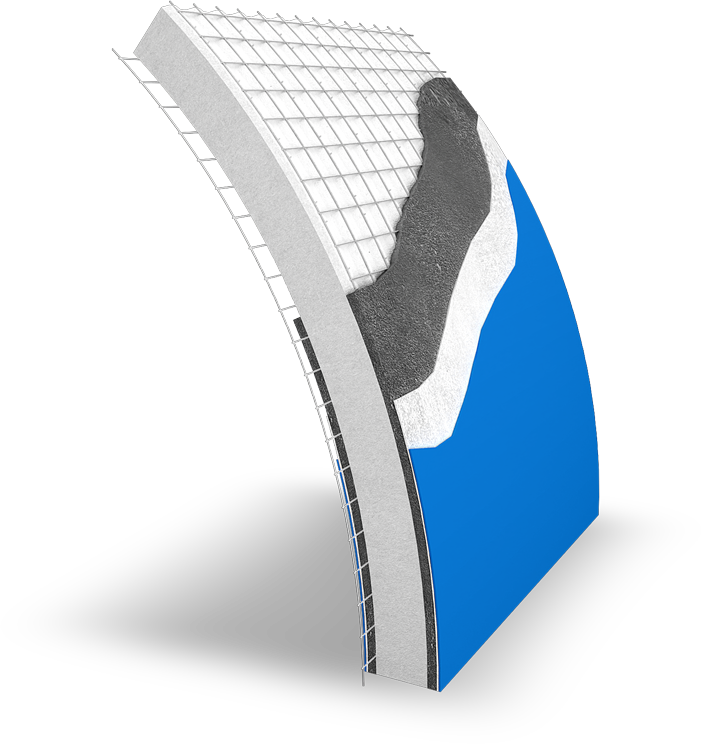

Steel reinforcement bars are placed within the mold according to the structural engineering specifications. These rebar grids provide tensile strength to the panel, reinforcing it against stresses such as bending or stretching.

Once the rebar is in place, an insulation layer is installed inside the mold. This layer improves the panel's thermal performance, making it more energy-efficient. The type and thickness of insulation can vary based on project requirements.

The concrete mix used should have the appropriate strength and consistency for the project is then shot-creted at site. The shot-crete is done carefully to ensure it covers the rebar and insulation evenly.

After curing, the concrete panel may undergo finishing processes to achieve the desired texture, colour, or appearance.